Production Manufacture

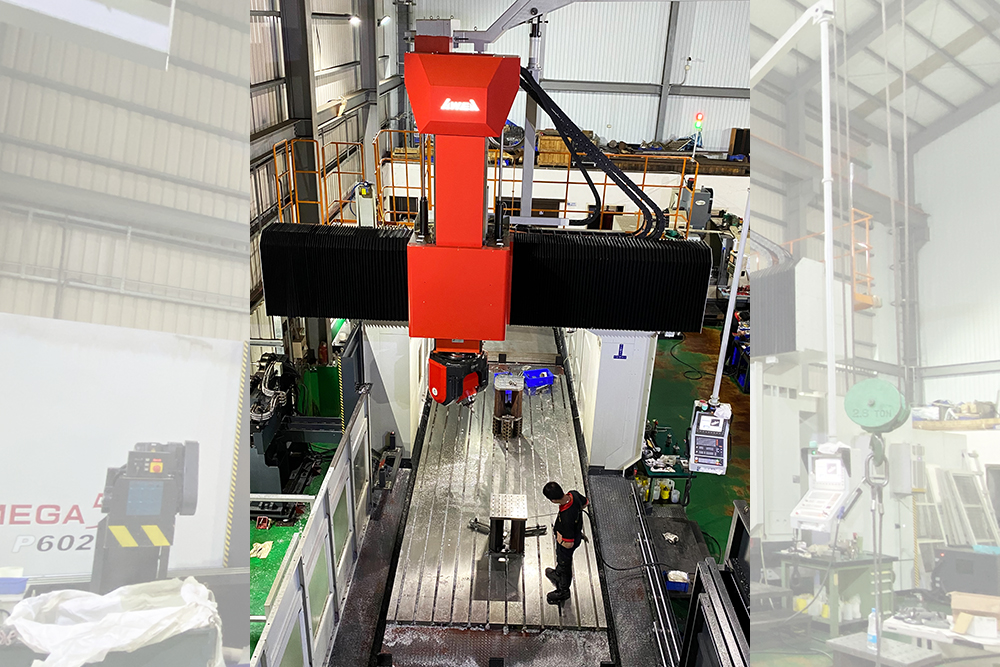

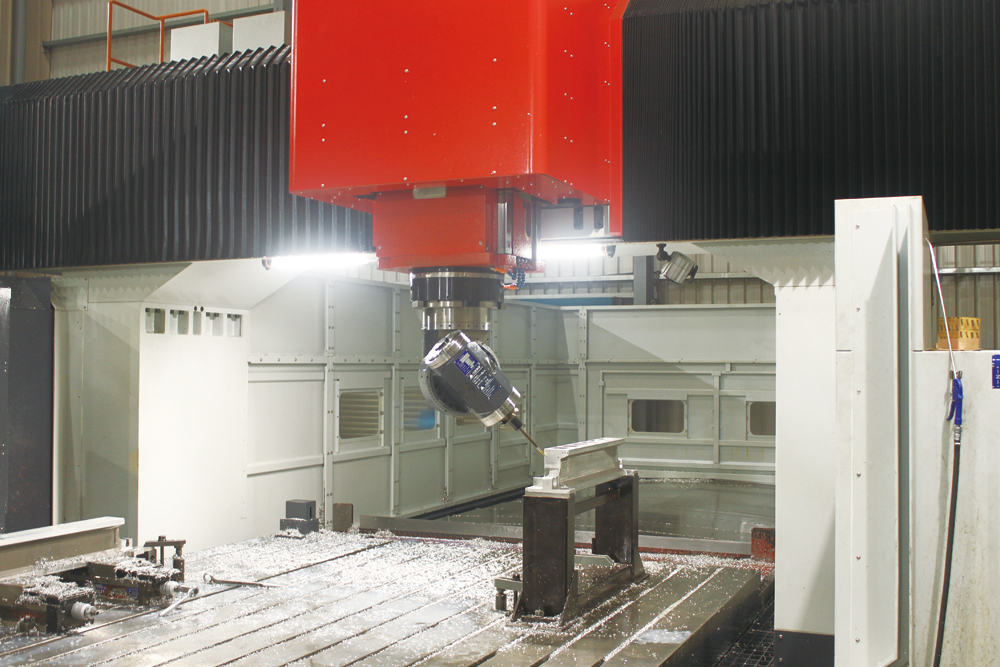

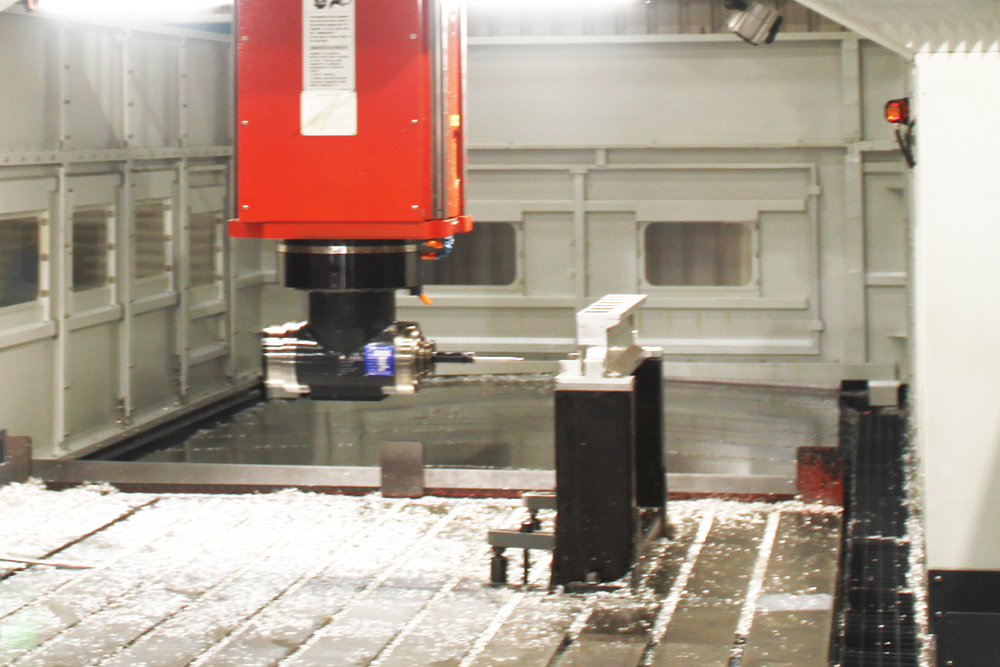

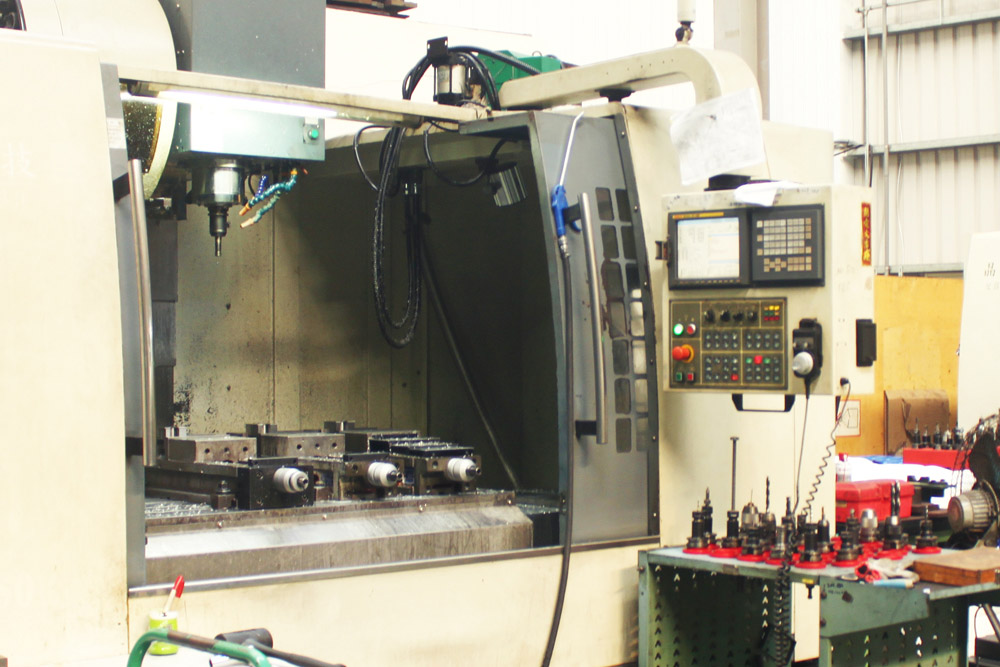

Wei Sheng Industrial operates a comprehensive CNC machining facility equipped with 5-axis gantry machining centers, multiple CNC gantry mills, horizontal boring machines, vertical milling machines, and supporting grinding and planing equipment. Our capabilities cover large-scale machining, precision component manufacturing, and complex multi-surface operations. With long-travel, high-rigidity machines capable of 5-face and 5-axis machining, we process aluminum alloys, stainless steel, carbon steel, tool steel, and various industrial materials for automation equipment parts, mechanical structures, vacuum equipment components, machine bases, jigs, and custom-made industrial parts.

Our production process integrates stable machining control, tool management, fixture planning, and precision inspection using CMMs, projectors, and multi-point measurement systems to ensure dimensional accuracy and consistent tolerances. Located in Yangmei, Taoyuan, Wei Sheng Industrial delivers high-precision machining, cross-process manufacturing integration, and reliable on-time performance, making us a trusted partner for large workpiece machining and high-accuracy manufacturing in both domestic and international markets.

Production Equipment List

Wei Sheng Industrial, located in Yangmei, Taoyuan, provides complete CNC machining capabilities, including 5-axis gantry machining centers, CNC gantry milling machines, horizontal boring machines, vertical CNC mills, laser cutting systems, and sheet-metal fabrication equipment. Our machining capacity supports large workpieces, precision components, and multi-axis complex machining. We process aluminum alloys, stainless steel, carbon steel, tool steel, and various industrial materials for automation equipment parts, mechanical structures, vacuum equipment, semiconductor components, steel frames, and custom-made industrial parts. With integrated CNC milling, 5-axis machining, deep-hole boring, sheet-metal forming, and metal laser cutting, Wei Sheng Industrial delivers one-stop metal manufacturing and large-scale machining solutions. We are a trusted CNC machining partner in Taoyuan, offering high-precision machining, large-gantry milling capabilities, and reliable production for domestic and international industries.

| Equipment | Equipment Name | Travel / Machining Range | Applicable Workpieces & Applications |

| CNC Gantry Milling Machines | CCNC Gantry Milling Machines | 8,000 × 4,200 × 1,600 mm((5-face machining) | Automation equipment bases, machine beds, steel structures, large mechanical components, vacuum equipment frames, and other large workpieces. |

| 6,000 × 3,500 × 1,600 mm(5-face machining, universal head) | |||

| 6,000 × 2,700 × 1,300 mm(5-axis gantry machining) | |||

| 4,200 × 2,800 × 1,600 mm (4-axis + universal head) | |||

| 4,000 × 2,000 × 1,200 mm | |||

| 3,000 × 1,800 × 800 mm(2 pcs) | |||

| CNC Horizontal Boring Machines | CNC Horizontal Boring Machines | 4,000 × 2,000 × 1,500 mm | Machine bases, housings, flanges, heavy plate structures, and workpieces requiring deep-hole machining. |

| 1,400 × 1,200 × 1,200 mm | |||

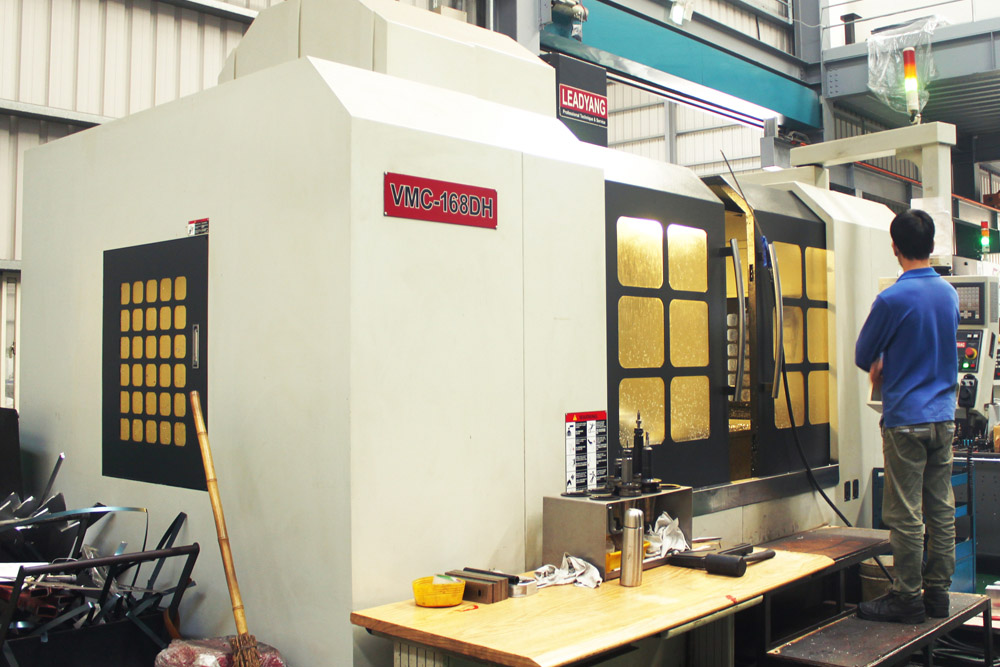

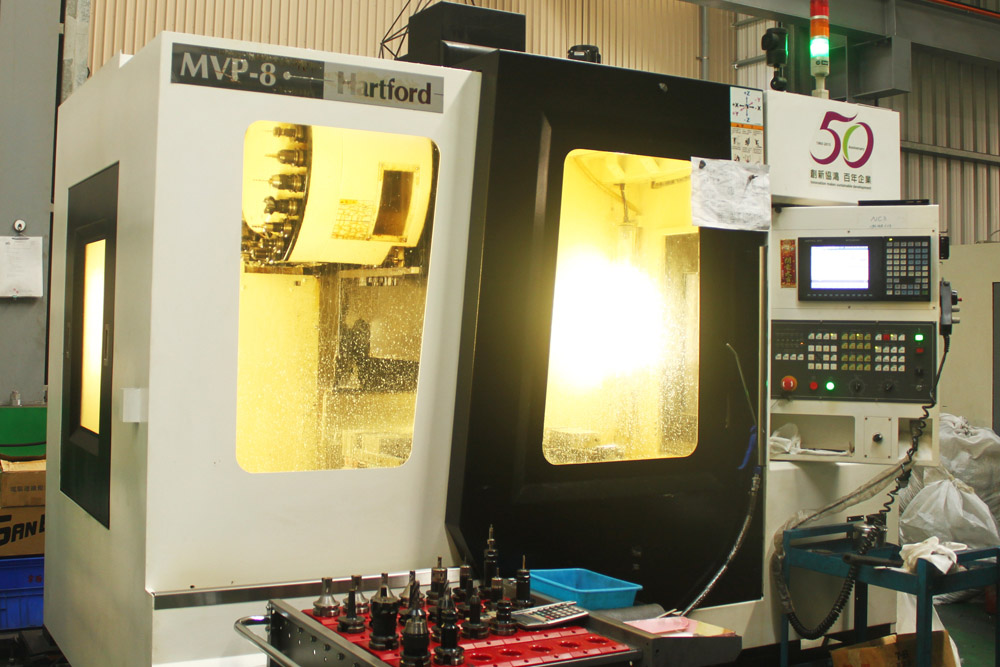

| CNC Milling Machines | Vertical CNC Milling Machine | 1,600 × 870 × 700 mm | Precision mechanical parts, fixtures, small automation components, and general mechanical parts. |

| 1,500 × 750 × 600 mm | |||

| 1,400 × 650 × 700 mm | |||

| 1,300 × 800 × 500 mm | |||

| 1,300 × 650 × 550 mm | |||

| 1,100 × 650 × 550 mm | |||

| 1,100 × 600 × 450 mm(4.5-axis machining) | |||

| 750 × 350 × 250 mm | |||

| Sheet Metal Bending Equipment | Hydraulic / CNC Bending Machine |

- |

Machine enclosures, control panels, sheet metal structures, bent sheet components. |

| Laser Cutting Machines | KANFON Laser Cutting Machine | Sheet Cutting Range 3,050 × 1,570 mm | Stainless steel, aluminum plates, steel plates, sheet metal parts, mechanical covers, and structural flat components. |

| Tube Laser Cutting | MAZAK 3D FABRI GEAR MkIII 4.0kW Tube Laser Machine | Loading length:12 m、Unloading length: 12 m | Structural tubing, machine frames, steel pipe components, supports, and welded frame structures. |

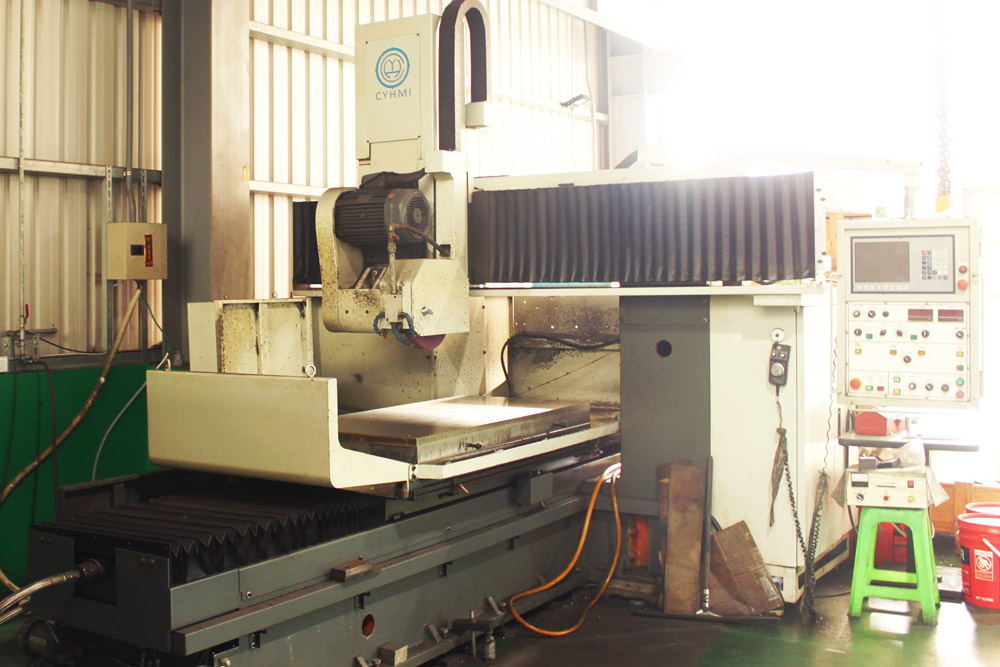

| Conventional Machining Equipment | Gantry Planer Machine | 4,000 × 1,600 × 1,200 mm | Machine beds, guideways, preparation machining for large structural components |

| Conventional Machining Equipment | Grinding Machine | 7,500 × 1,500 mm | Large plates, machine bases, slideways, and components requiring high flatness. |

| Welding Equipment | CO₂ Welding Machines, Cold Welders, 6,000 × 4,000 mm Welding Table, Welded Frame Fixtures | - | Machine frames, equipment structures, steel structural parts, and custom welded assemblies. |

►Double-Column Machining Center

► CNC Horizontal Boring Mill

► CNC Milling Machines

► CNC Hydraulic Press Brake

► KANFON Laser Cutting Machine

► MAZAK 3D FABRI GEAR MkIII 4.0kW Tube Laser Cutting Machine