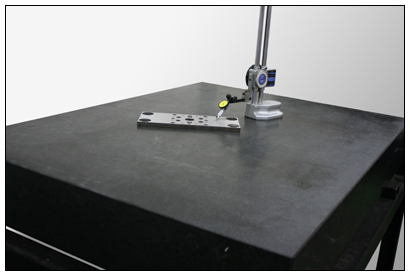

Inspection Equipment

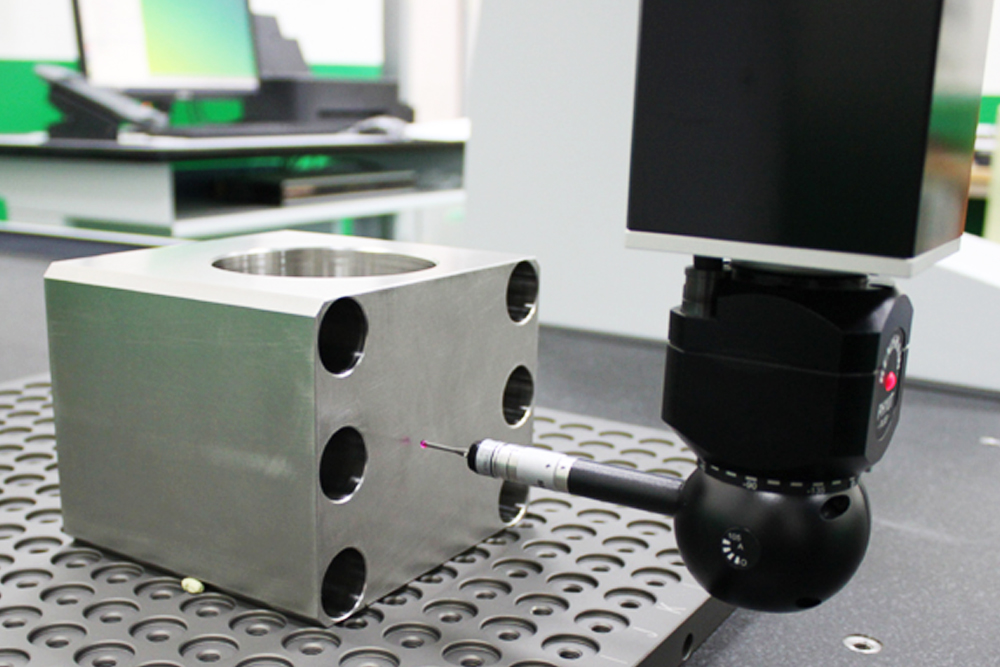

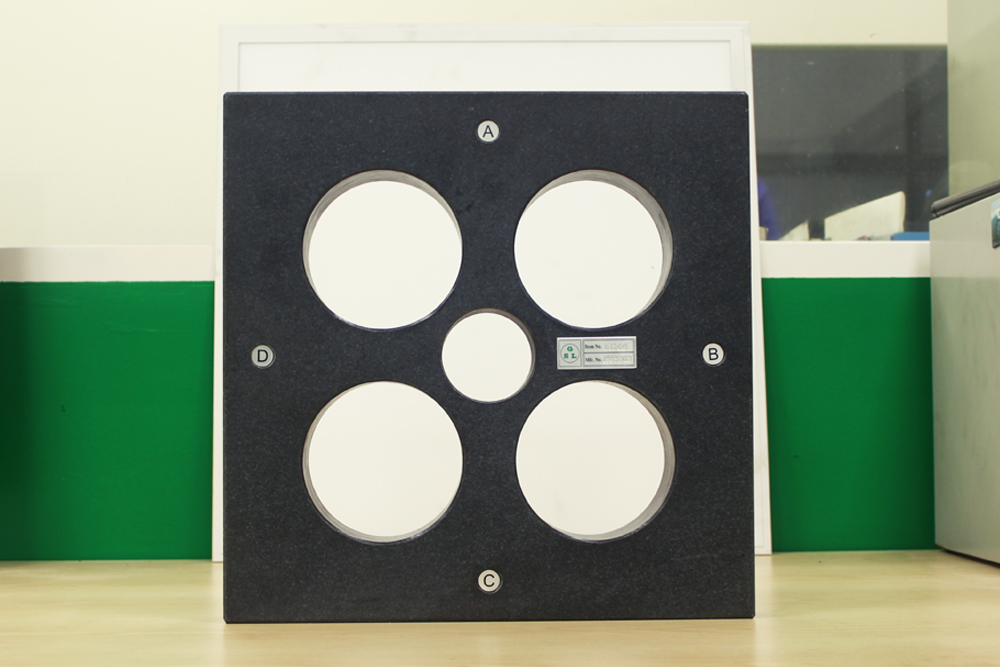

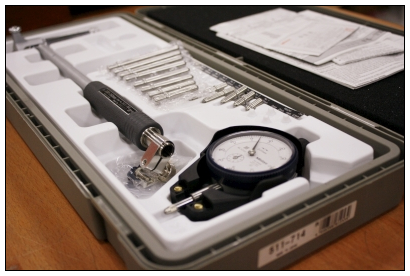

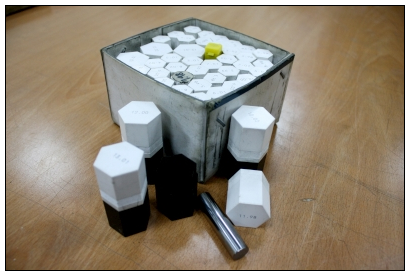

Wei Sheng Industrial provides comprehensive CNC machining quality control supported by advanced inspection equipment, including CMM (Coordinate Measuring Machine), height gauges, optical projectors, surface roughness testers, and various precision measuring tools. These instruments enable full dimensional inspection and tolerance verification for large workpieces, 5-axis machined components, gantry-milled parts, horizontal boring parts, and sheet-metal or laser-cut components. We conduct detailed checks for dimensions, flatness, perpendicularity, hole-position accuracy, and assembly fit to ensure all CNC-machined and metal-fabricated parts meet engineering specifications.

Through strict IQC incoming inspection, IPQC in-process quality control, and FQC final inspection processes, Wei Sheng Industrial maintains high-precision and consistent quality across 5-axis machining, CNC gantry milling, deep-hole boring, sheet-metal bending, and laser cutting operations. Our advanced inspection capability and structured quality system make us a trusted CNC machining and metal fabrication quality-control partner in the Taoyuan region.